Sensor integration

Consolidate and capture key signals

Data pipelines

Reliable capture, transport & storage

Sensor validation

Detect drift, faults, and outliers

Dashboards & alerts

Operational KPIs, alarms and insights

Performance evaluation

Operational Kpis, alarms and insights

A complete monitoring fundation

Sensor integration across systems and vendors

Reliable data capture and storage

Sensor validation and health monitoring

Dashboards, KPI's and alerts

Performance evaluation and optimization support

This allows you to move from fragmented data to consistent operation insights

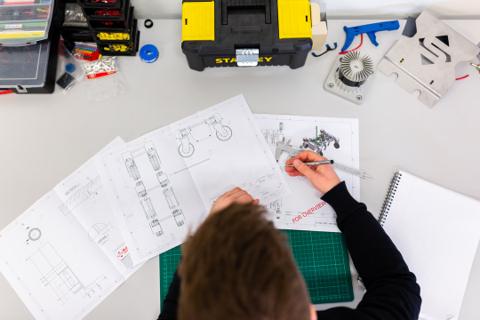

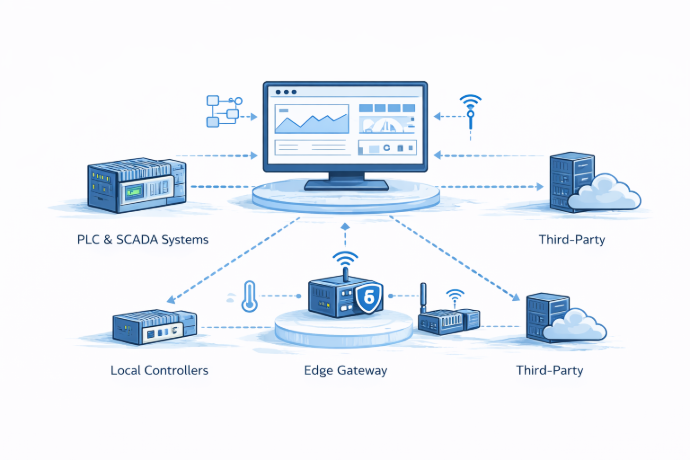

1) Sensor & System Integration

We integrate sensors and operational parameters from:

- PLC and SCADA systems

- local controllers (HVAC, pumps, heat systems, energy production)

- edge devices and gateways

- third-party platforms and vendor systems

Result: a unified view of all relevant operational signals

2) Reliable Data Capture

We design robust data pipelines with:

- time-synchronized measurements

- buffering and fail-safe logging

- secure transport and storage

- consistent naming and tagging conventions

Result: your monitoring works even when networks don’t.

3) Sensor Validation & Health Monitoring

We continuously evaluate the sensor layer:

- missing signals and communication loss

- drift detection and plausibility checks

- sensor consistency and redundancy comparisons

- calibration tracking and quality indicators

Result: you know what you can trust — and what needs attention.

4) Dashboards & Real-Time Monitoring

We create dashboards focused on action, not decoration:

- real-time status and KPI views

- alarm and event monitoring

- trend analysis

- role-specific views (operator vs management)

Result: faster situational awareness and less manual troubleshooting.

5) Performance Evaluation & Optimization Support

Monitoring only becomes valuable when it drives decisions.

We support:

- baseline performance modeling

- efficiency tracking

- waste detection (unnecessary heat loss, standby usage, poor scheduling)

- improvement suggestions and implementation support

Result: measurable improvements in reliability and energy cost.