AUTOMATION & INDUSTRIAL SYSTEMS

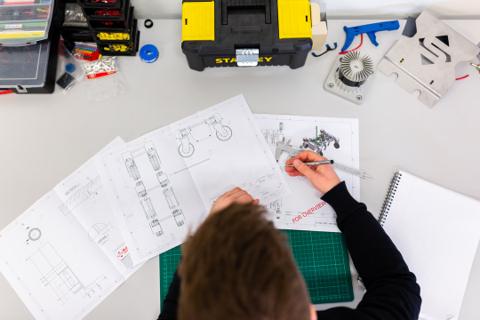

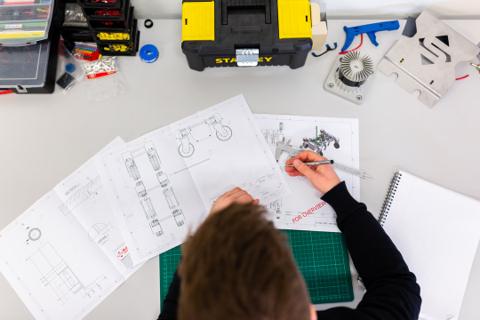

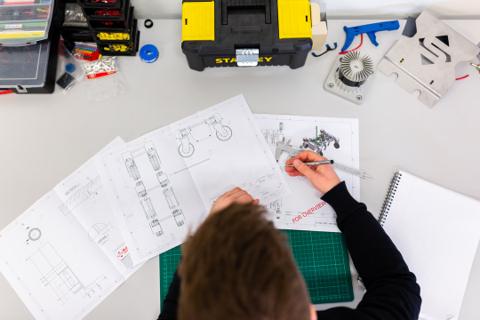

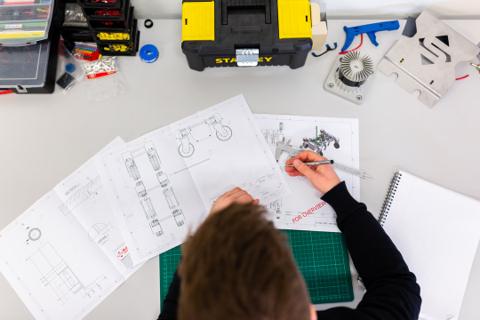

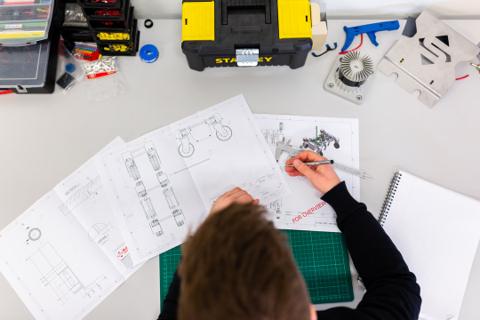

A complete automation foundation

We design, integrate, and deploy automation systems for industrial environments:

- Automation system design and integration

- Industrial control and data interfaces

- Commissioning and field deployment

- Manufacturing test and validation systems

- Operational optimization support

1) Requirements & System Architecture

We define the automation framework:

- Control objectives and constraints

- Interfaces between sensors, actuators, and control systems

- Acceptance criteria and test strategy

Result: Fewer integration surprises during deployment.

2) Automation & Control Implementation

We implement control logic and system behavior:

- Sequencing and interlocks

- Fail-safe and fallback operation

- Diagnostics and operational modes

Result: Stable and predictable industrial operation.

3) Industrial Integration

We integrate with existing industrial systems:

- PLC and SCADA environments

- Vendor-specific equipment and gateways

- Monitoring and historian systems

Result: One coherent system instead of isolated subsystems.

4) Commissioning & Field Deployment

We support deployment and handover:

- Onsite bring-up and tuning

- Operator documentation and training support

- Acceptance testing assistance

Result: Faster go-live with fewer operational issues.

5) Manufacturing Test & Validation Systems

We build test systems for production environments:

- End-of-line tests and fixtures

- Data logging and quality verification

Result: Higher consistency and faster fault detection.